Product Description

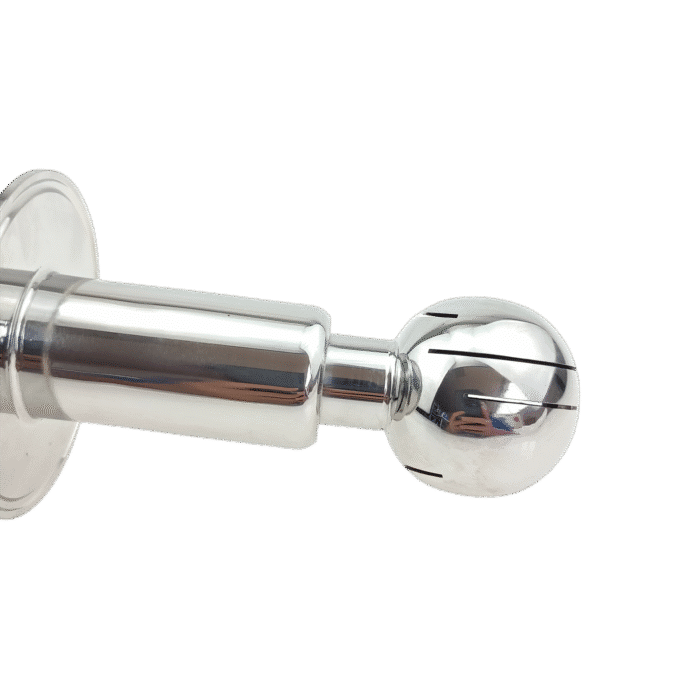

360degree Rotating CIP Spray Ball 1.5″ Tri-Clamp on 3″ Tri-Clamp Cap

3″ Tri Clamp Cap Spray Ball with 1.5″ Tri Clamp Compatible Inlet – 304 Stainless Steel – Used to continuously coat the inside of a vessel with liquid for clean in place (CIP) applications.

Specs:

Overall Length: 7.48”

Connection Outer Diameter: 1.98″

Connection Inner Diameter: 1.35″

Tri-Clamp Cap Diameter: 3.58” (the bigger cap)

Ball Diameter: 2.08”

Compatibility: 3″ TC | 1″ TC | 1.25″ TC | 1.5″ TC

Material: 304 Stainless Steel

Frequently asked questions

FAQ for 360 Degree Rotating CIP Spray Ball 1.5″ Tri-Clamp on 3″ Tri-Clamp Cap

Q1: What is a CIP Spray Ball?

A CIP (Clean-In-Place) Spray Ball is a type of cleaning device used in various industries, particularly in food and beverage, pharmaceuticals, and biotechnology. It is designed to clean tanks, pipes, and other equipment without needing to disassemble the equipment. The 360-degree rotation ensures that cleaning solutions reach all areas effectively.

Q2: What are the dimensions of the spray ball?

The spray ball features a 1.5″ Tri-Clamp connection, which allows it to be easily attached to a corresponding 1.5″ tri-clamp fitting. It is mounted on a 3″ Tri-Clamp cap, providing a secure and reliable connection to larger pipelines or equipment.

Q3: Why should I choose a rotating spray ball?

A rotating spray ball provides superior coverage compared to stationary spray systems, ensuring that all surfaces are effectively cleaned. This is particularly important in industries where hygiene is critical, as it helps prevent contamination and ensures compliance with sanitation standards.

Q4: What materials are used to manufacture this spray ball?

The spray ball is typically made from stainless steel, which is resistant to corrosion and easy to clean. Stainless steel is an ideal choice for applications involving food and pharmaceuticals, as it is non-reactive and maintains the integrity of the products being processed.

Q5: How do I install the spray ball?

Installation involves securing the spray ball through the 3″ Tri-Clamp cap onto the desired connection. Ensure that all components are properly aligned and tightened to prevent leaks during operation. It’s advisable to follow specific manufacturer guidelines and best practices for installation.

Q6: Can the spray ball be used in different applications?

Yes, the 360-degree rotating CIP spray ball can be used in various applications, including cleaning fermentation tanks, storage tanks, and other types of processing equipment in the food, beverage, and pharmaceutical industries.

Q7: Is maintenance required for the spray ball?

Regular inspection and cleaning are recommended to ensure optimal performance and longevity. Checking for wear, blockages, or any residual build-up after use can help maintain the efficiency of the spray ball.

Q8: Are there any compatibility issues I should be aware of?

As long as your equipment is compliant with the tri-clamp standards, the 1.5″ Tri-Clamp spray ball on a 3″ tri-clamp cap should fit well. However, always verify compatibility with your specific setup and application needs.

Q9: Where can I purchase a 360 Degree Rotating CIP Spray Ball?

You can purchase a 360 Degree Rotating CIP Spray Ball from various manufacturers, industrial supply stores, or online retailers specializing in sanitary equipment. Always consider reviewing product specifications to ensure they meet your requirements.

Q10: What is the expected lifespan of the spray ball?

The lifespan of the spray ball depends on its usage, maintenance, and the conditions in which it operates. With proper care and regular maintenance, a high-quality stainless steel spray ball can last for several years.