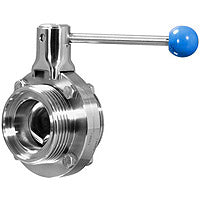

Product Description

1.5″ tri clamp sample valve classic type

- Constructed by SS304 stainless steel.

- polish inside and outside.

- Food grade silicone sealing.

Frequently asked questions

Frequently Asked Questions (FAQ) about Sanitary 1.5″ Tri Clover Compatible x 3/8″ Sample Valve Silicone Sealing

1. What is a Sanitary 1.5″ Tri Clover Compatible x 3/8″ Sample Valve Silicone Sealing?

It is a specialized sealing solution designed for use in sanitary applications that require compatibility with 1.5″ Tri Clover fittings and feature a 3/8″ sample valve. Made from high-quality silicone, it ensures a proper seal for efficient operation and hygiene standards.

2. What materials are used in the construction of this sealing?

This sealing is made from premium silicone, which is known for its durability, flexibility, and resistance to high temperatures and chemicals. This makes it suitable for various sanitary applications.

3. What are the benefits of using silicone for sealing?

Silicone provides excellent sealing capabilities, is resistant to compression set, and maintains its elasticity over a wide temperature range. It also resists degradation from exposure to a variety of chemicals, making it ideal for sanitary environments.

4. How do I install the Sanitary 1.5″ Tri Clover Compatible x 3/8″ Sample Valve Silicone Sealing?

To install, ensure the mating surfaces are clean and free of debris. Simply place the silicone sealing onto the flange of the Tri Clover fitting and securely attach the sample valve. Make sure to follow standard protocols for tightening to avoid over-compression.

5. What are the applications for this silicone sealing?

This sealing is commonly used in food and beverage processing, pharmaceuticals, biotech industries, and any application requiring hygienic sample collection or transfer while maintaining strict sanitary conditions.

6. How do I ensure the longevity of the sealing?

To ensure the longevity of the sealing, avoid exposing it to harsh chemicals, excessive heat, or mechanical stress. Regular inspections and replacing worn or damaged seals will help maintain optimal performance.

7. Are there any compatibility issues I should be aware of?

While the sealing is designed to be compatible with standard 1.5″ Tri Clover fittings and 3/8″ sample valves, users should ensure that their specific equipment is compliant with these standards to avoid fitment issues.

8. Where can I purchase the Sanitary 1.5″ Tri Clover Compatible x 3/8″ Sample Valve Silicone Sealing?

This product can be found at various industrial supply stores, specialty sanitary equipment suppliers, or online marketplaces that focus on food-grade and sanitary processing equipment.

9. Can I use this sealing for non-sanitary applications?

While it is designed for sanitary applications, using it in non-sanitary applications may not be advisable, as the sealing is optimized for cleanliness and could be overkill for standard mechanical uses.

10. What should I do if I experience issues with the sealing?

If you experience issues such as leaks or improper fit, check the installation for obstructions or damage. If problems persist, consider replacing the sealing or consulting with a representative for further troubleshooting assistance.