Product Description

Rotary CIP Spray Ball is used to continuously coat the inside of a vessel with liquid for clean in place (CIP) applications.This 1/2 inch FNPT Connection to tri clamp spray balls are operate on 15-100PSI, 40-60PSI is recommended. This type is mounted on a standard tri clover compatible flange and go through a clamp ferrule. Each cip ball go through 5.88 inch into the vessel. All of Ace cip cleaning balls are contructed 304 Stainless Steel, no use 201 stainless steel .

- All input is 1/2″ female threaded end.

- 1/2″*1.5″ version fit 1.5″ tri clamp ferrule, the ferrule inner diameter must 35mm.

- 1/2″*3″ version fit 3″ tri clamp ferrule.

- 1/2″*4″ version fit 4″ tri clamp ferrule.

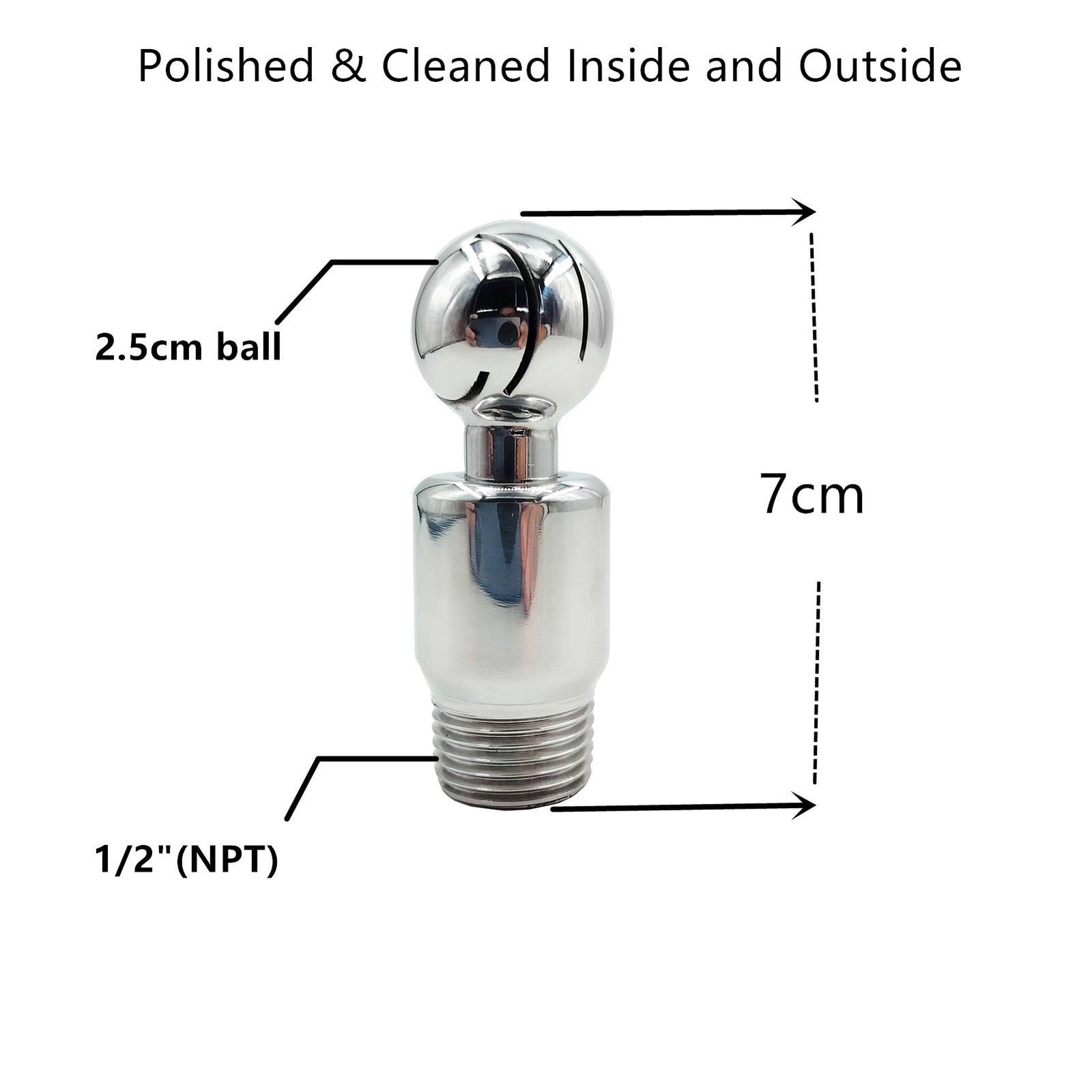

- Please check drawing for more dimensions.

Frequently asked questions

FAQ: Rotating CIP Spray Ball 1/2 inch Female NPT Connection to Tri Clamp Flange Mount 360 Degree Rotary Tank Cleaning Ball

What is a Rotating CIP Spray Ball?

The Rotating CIP Spray Ball is a cleaning device designed to efficiently clean the interior surfaces of tanks and other vessels. It utilizes a rotating mechanism to provide a thorough 360-degree spray coverage, ensuring that all areas are reached and cleaned effectively.

What is CIP?

CIP stands for Clean-In-Place, which is a method used to clean the interior surfaces of pipes, vessels, and equipment without the need to dismantle them. CIP systems typically involve the use of hot water, cleaning agents, and sanitizers that are circulated through the system.

What are the connection specifications?

This spray ball features a 1/2 inch female NPT (National Pipe Thread) connection, allowing it to be easily integrated into various piping systems. It is also designed to mount onto a tri-clamp flange for secure installation.

What materials is the spray ball made of?

The Rotating CIP Spray Ball is typically made from high-quality stainless steel, which is resistant to corrosion and ensures durability in high-temperature and high-pressure situations.

How does the rotating mechanism work?

The rotating mechanism is powered by the flow of the cleaning liquid. As liquid is pumped through the spray ball, it creates pressure that causes the ball to rotate. This rotation helps distribute the cleaning solution evenly and thoroughly across all surfaces.

What applications is this spray ball suitable for?

This spray ball is suitable for various applications, including food and beverage processing, pharmaceuticals, and chemical manufacturing, where cleanliness and sanitation are critical.

How do I install the spray ball?

To install the spray ball, ensure that the tri-clamp flange is compatible with your system. Securely attach the 1/2 inch female NPT connection to the appropriate piping. Follow manufacturer instructions for proper alignment and tightening to prevent leaks.

What is the cleaning efficiency of this spray ball?

The cleaning efficiency is very high due to the 360-degree rotary action that allows for comprehensive coverage. It can effectively remove residues, dirt, and microbial contaminants from tank surfaces when used within recommended pressure and flow rate specifications.

Can this spray ball be used with varying cleaning solutions?

Yes, the rotating CIP spray ball can be used with a variety of cleaning solutions, including caustics, sanitizers, and acids, depending on your cleaning requirements. Always consult the cleaning agent manufacturer’s recommendations to ensure compatibility.

How do I maintain the rotating spray ball?

Regular maintenance involves inspecting the spray ball for wear or damage, ensuring that the connection points are secure, and cleaning any build-up that may occur. Periodic testing of the cleaning efficacy is also recommended to ensure optimal performance.