Product Description

This rotary cleaing ball is a efficient CIP (Clean in Place) solution for running cleaners and sanitizers through small opening vessels including:

- Sanke kegs.

- Conical fermenters.

- Standard glass and plastic carboys .

- Speidel fermenters and plastic storage tanks.

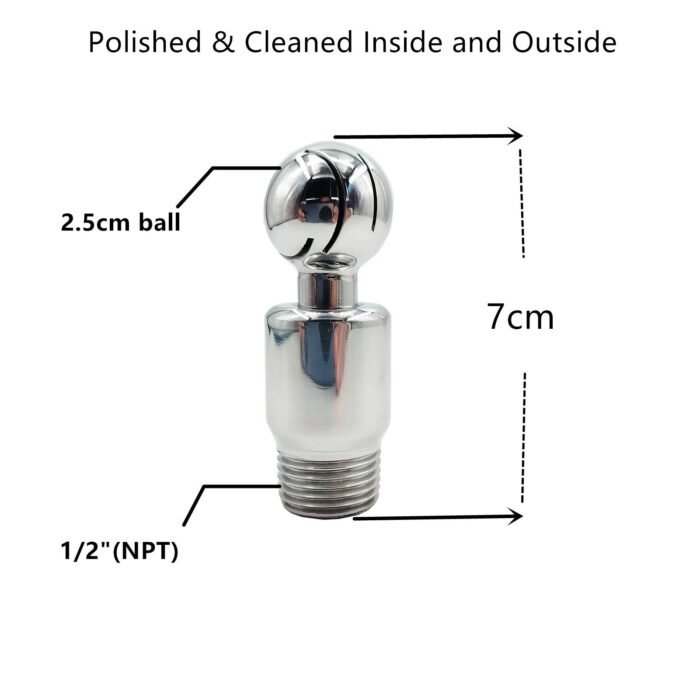

Specs:

- 304 Stainless Steel material of all parts.

- 1 inch diameter ball and body, 2.75 inches overall long.

- 0.5inch male NPT connection (outer diameter is 3/4 inch).

- we cleaned and polished inside and outside.

Frequently asked questions

FAQ about Mini Rotating Spray Ball 1/2″ Male NPT Connection 304 Stainless Steel CIP

Q1: What is a mini rotating spray ball?

A mini rotating spray ball is a cleaning device used in various industries, particularly in food and beverage processing, to effectively clean tanks and other equipment. It operates by spraying cleaning solutions in a radial pattern to ensure comprehensive coverage and cleaning.

Q2: What is the significance of the 1/2″ Male NPT connection?

The 1/2″ Male NPT (National Pipe Thread) connection allows for easy installation of the spray ball to existing piping systems. This standardized fitting ensures compatibility with a wide range of equipment without requiring additional adapters.

Q3: Why is 304 stainless steel used in the construction of the spray ball?

304 stainless steel is renowned for its corrosion resistance and durability, making it an ideal material for equipment exposed to cleaning solutions and varying temperatures. It is also non-reactive, ensuring that it does not contaminate the cleaning process.

Q4: What does CIP stand for, and why is it important?

CIP stands for Clean-In-Place. This cleaning method allows for the internal cleaning of equipment without needing to disassemble it. The mini rotating spray ball facilitates CIP processes by delivering optimal cleaning solutions directly to the interior surfaces of the equipment.

Q5: How does the rotating feature benefit cleaning efficiency?

The rotating feature allows the spray ball to distribute cleaning solutions evenly across surfaces. This enhances the cleaning effectiveness by reaching more areas, including those that may be difficult to access with traditional cleaning methods.

Q6: Can the mini rotating spray ball be used with different cleaning chemicals?

Yes, the mini rotating spray ball can be used with a variety of cleaning chemicals, including detergents and sanitizers. However, it is essential to ensure that the chemicals used are compatible with 304 stainless steel to avoid any potential damage.

Q7: What is the ideal pressure and flow rate for optimal operation?

The ideal pressure and flow rate can vary depending on the specific application and cleaning requirements. Generally, it is recommended to operate the spray ball within the manufacturer’s guidelines, typically around 20-50 PSI, to ensure effective coverage and cleaning.

Q8: Is maintenance required for the mini rotating spray ball?

Minimal maintenance is required. However, periodic inspections for wear and tear, as well as ensuring all connections are secure and free from clogs, will help maintain optimal performance. Regularly cleaning the spray ball to prevent buildup is also advisable.

Q9: Where can I purchase the mini rotating spray ball?

The mini rotating spray ball can be purchased from various industrial supply companies, specialized equipment suppliers, and online marketplaces focusing on processing and cleaning equipment.

Q10: What are the applications of the mini rotating spray ball?

This spray ball is widely used in the food and beverage industry, pharmaceuticals, breweries, and any other sectors requiring stringent hygiene standards for tank and equipment cleaning.