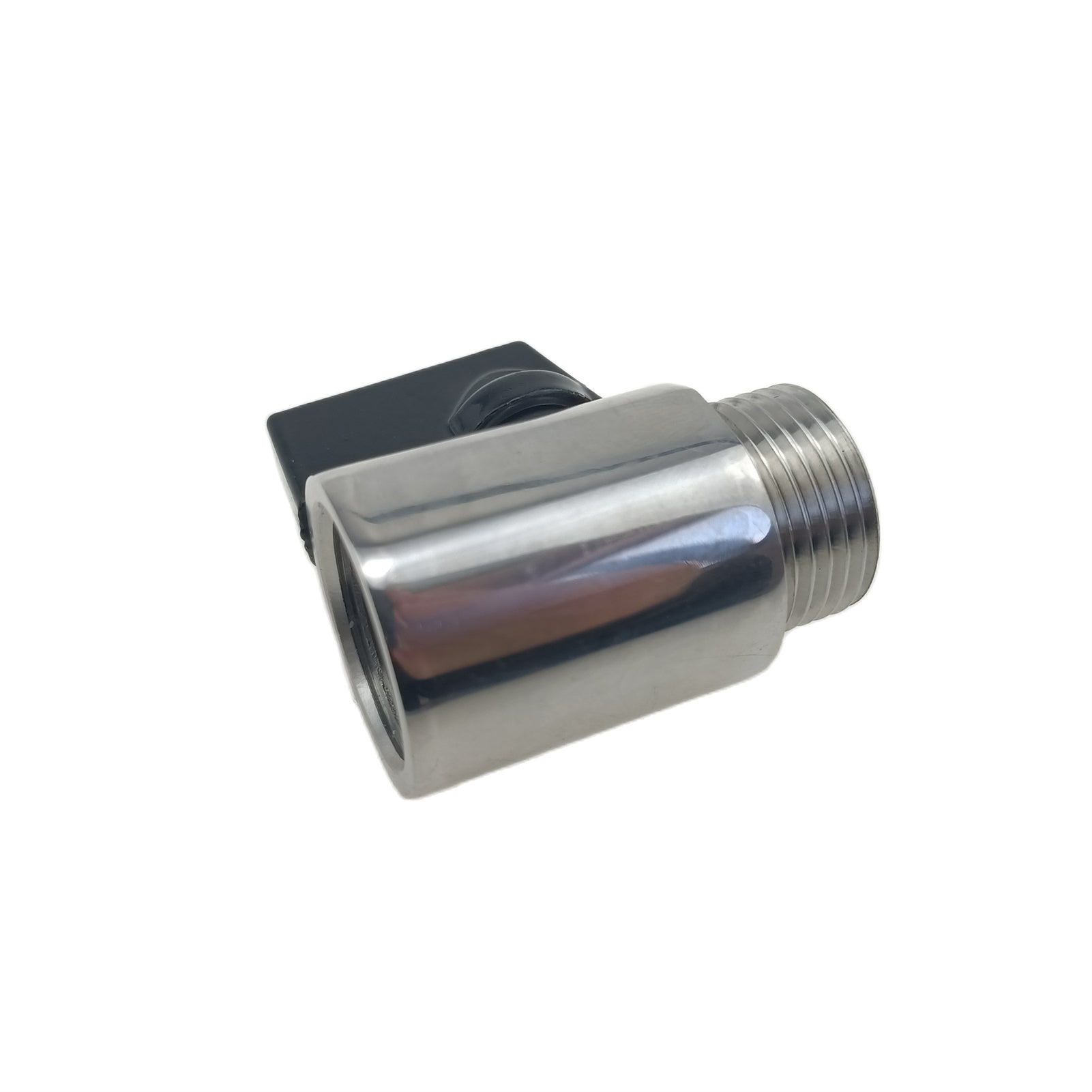

Product Description

Sanitary diaphragm valve are made from stainless steel SS316, and come with double gaskets: EPDM and PTFE. The sanitary design allows precise control of the fluid flow rate with low turbulence and minimal back pressure.

- 20RA ID (SF1)

- 316L

- EPDM/PTFE diaphragm

- available for pneumatic

Frequently asked questions

FAQ about Tri Clover Compatible Diaphragm Valve SS316L EPDM+PTFE Sealing

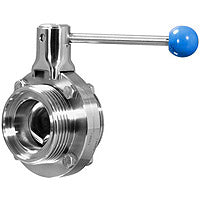

1. What is the Tri Clover Compatible Diaphragm Valve?

The Tri Clover Compatible Diaphragm Valve is a type of valve that is designed to work seamlessly with Tri Clover (also known as Tri-Clover) fittings. It uses a diaphragm mechanism to control the flow of liquids, making it suitable for hygienic applications in food, beverage, and pharmaceutical industries.

2. What materials are used in the valve?

This diaphragm valve is made from SS316L stainless steel, which is known for its corrosion resistance and durability. It features EPDM (Ethylene Propylene Diene Monomer) and PTFE (Polytetrafluoroethylene) sealing materials that provide excellent resistance to chemicals and high temperatures.

3. What are the benefits of using SS316L stainless steel?

SS316L is a low-carbon stainless steel that offers enhanced resistance to pitting corrosion in chloride environments. It is ideal for applications where hygiene and cleanliness are paramount, as it is easily cleaned and sanitized.

4. Why are EPDM and PTFE used for sealing?

EPDM is an elastomer that provides excellent flexibility, temperature resistance, and weather resistance, making it suitable for many fluid handling applications. PTFE is known for its low friction properties and high chemical resistance. The combination of both materials ensures reliable sealing under various conditions.

5. Can this valve be used in high-temperature applications?

Yes, the Tri Clover Compatible Diaphragm Valve can withstand high temperatures due to its stainless steel construction and the properties of the EPDM and PTFE seals. However, it is important to check the specific temperature ratings of the seals to ensure compatibility with your application.

6. Is this valve suitable for sanitary applications?

Yes, this valve is designed with sanitary applications in mind. Its construction and sealing materials prevent contamination, making it an ideal choice for industries like food processing, pharmaceuticals, and biotechnology.

7. How do I install the diaphragm valve?

The installation process will vary based on your specific system. Generally, it involves aligning the valve with existing piping and securing it with Tri Clover clamps. It is advisable to follow manufacturer instructions and industry best practices during installation.

8. How do I maintain the valve?

Regular maintenance is essential for optimal performance. Inspect the seals for wear and tear, clean the valve and surrounding area to prevent contamination, and ensure that any moving parts are functioning properly. Replace seals as necessary to maintain integrity.

9. Where can I find replacement parts for this valve?

Replacement parts for Tri Clover Compatible Diaphragm Valves can often be obtained from the manufacturer or authorized distributors. You can check online retailers or contact your local supplier for availability.

10. What industries typically use these valves?

This type of diaphragm valve is commonly used in industries such as food and beverage processing, pharmaceutical manufacturing, biotechnology, and other sanitary environments where maintaining hygiene is crucial.