Product Description

Features:

- Normally Closed.

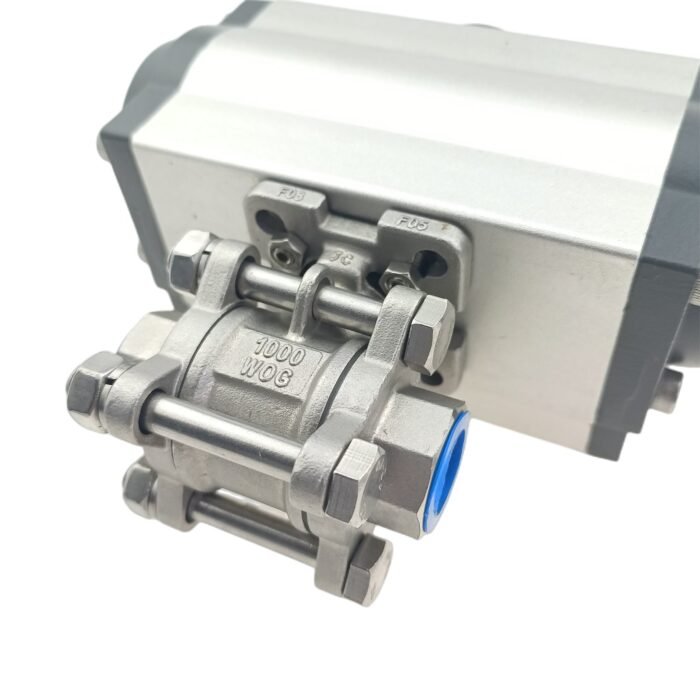

- SS304 stainless steel valve, PTFE seat.

- -20℃ to 180℃.

- 1000 psi WOG.

- Repair kit includes valve seat and bolts.

Frequently asked questions

Frequently Asked Questions (FAQ) about Stainless Steel Double Acting NC Pneumatic Actuated FNPT Threaded Ball Valve

Q1: What is a stainless steel double acting NC pneumatic actuated ball valve?

A1: A stainless steel double acting NC (normally closed) pneumatic actuated ball valve is a valve that controls the flow of fluids through a pipe. It utilizes pneumatic pressure to open and close the valve, and is designed to remain closed when no pressure is applied. This type of valve is commonly used in various applications for its durability and reliability.

Q2: What does FNPT stand for?

A2: FNPT stands for Female National Pipe Thread. This designation indicates that the valve has female threads for easy connection to other pipe fittings or equipment, ensuring a secure and tight fit.

Q3: What is a 3-pc bolted type valve?

A3: A 3-pc bolted type valve is constructed with three separate pieces: the body, the ball, and the end caps. This design allows for easy maintenance, as the valve can be disassembled for repairs or servicing without needing to replace the entire unit.

Q4: Is a repair kit included with the valve?

A4: Yes, the stainless steel double acting NC pneumatic actuated ball valve comes with a repair kit. The kit typically includes O-rings, seals, and other necessary components that may need to be replaced over time for the continued reliable operation of the valve.

Q5: What applications are suitable for this type of valve?

A5: This type of valve is suitable for various applications, including water treatment, chemical processing, food and beverage manufacturing, and gas distribution. Its stainless steel construction provides excellent resistance to corrosion and high temperatures, making it ideal for demanding environments.

Q6: How does the pneumatic actuation work?

A6: The pneumatic actuation works by using compressed air to operate the valve. The pressure is applied to one side of the actuating mechanism, which moves the valve’s ball to either open or close the valve. When the pressure is released, the valve returns to its default normally closed position.

Q7: What maintenance is required for this valve?

A7: Regular maintenance includes checking for leaks, ensuring that the pneumatic connections are secure, and inspecting the internal components using the repair kit provided. It is also advisable to periodically lubricate moving parts according to the manufacturer’s recommendations.

Q8: What are the advantages of using a stainless steel ball valve?

A8: The primary advantages of a stainless steel ball valve include its high durability, resistance to corrosion, high-temperature tolerance, and reliable sealing capability. Additionally, stainless steel valves often have a longer lifespan and require less frequent replacement compared to those made from other materials.